Understanding Kitchen Cabinet Dimensions and Space Planning

Effective kitchen design hinges on a thorough understanding of cabinet dimensions and their spatial arrangement. Optimizing space within a given area requires careful consideration of both standard cabinet sizes and the dimensions of major appliances. This ensures efficient workflow, ample storage, and a visually appealing kitchen layout.

Kitchen Layout for a 10ft x 12ft Space

This section details a sample kitchen layout optimized for a 10ft x 12ft space. The design prioritizes functionality and efficient use of space. Cabinet dimensions are provided as examples and may need adjustment based on specific appliance sizes and personal preferences.

| Cabinet Type | Dimensions (W x D x H) | Storage Capacity (Approximate) | Placement |

|---|---|---|---|

| Base Cabinets (Sink) | 36″ x 24″ x 34.5″ | High | Along sink wall |

| Base Cabinets (Standard) | 30″ x 24″ x 34.5″ | Medium | Along counter run |

| Wall Cabinets (Standard) | 30″ x 12″ x 30″ | Medium | Above counter run |

| Corner Base Cabinet | 36″ x 24″ x 34.5″ | High (with lazy susan) | Corner of counter run |

| Tall Pantry Cabinet | 18″ x 24″ x 84″ | Very High | Adjacent to refrigerator |

This layout assumes a standard 24-inch deep countertop. Adjustments may be needed based on specific appliance sizes and personal preferences. The suggested arrangement aims for a smooth workflow triangle between the sink, stove, and refrigerator.

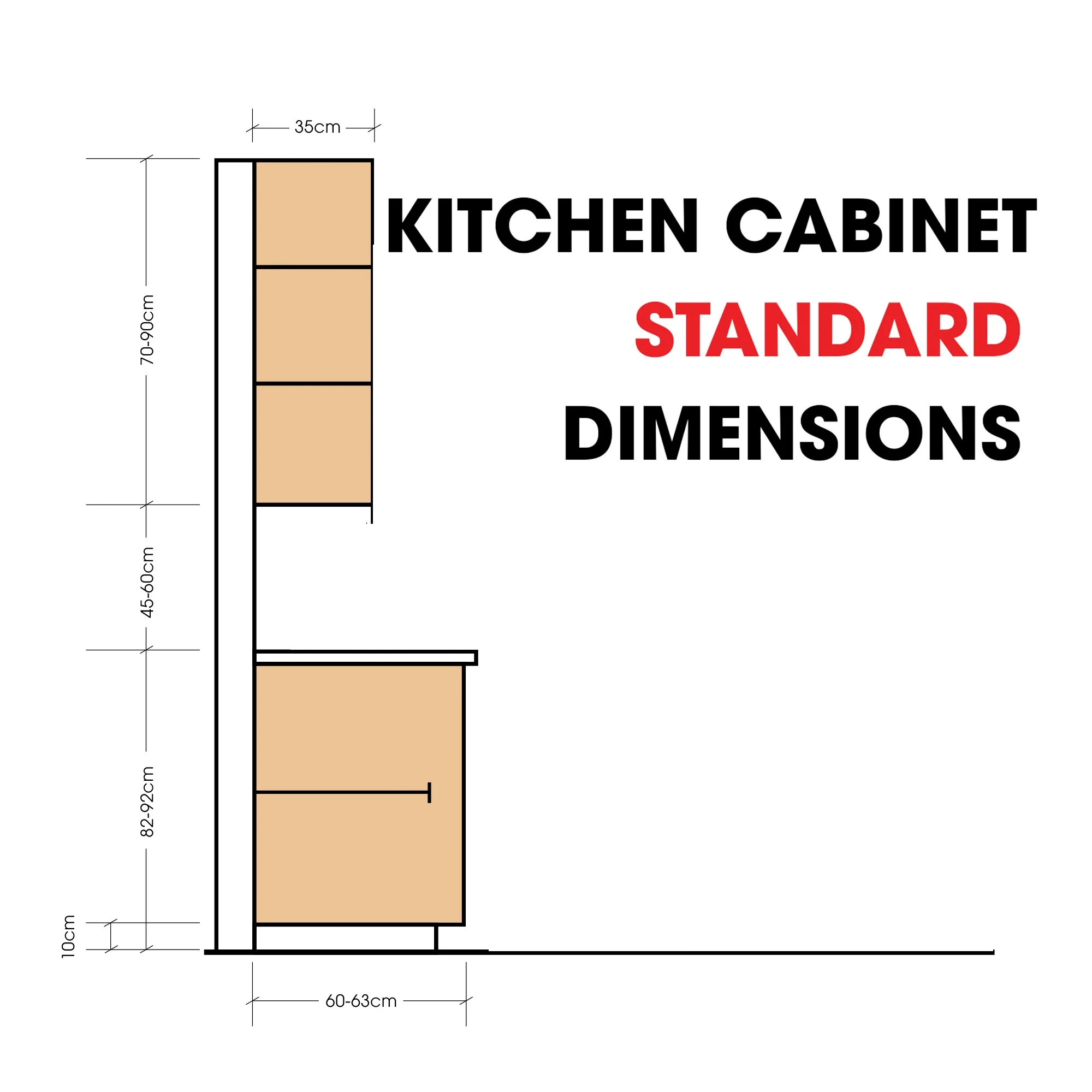

Standard Cabinet Dimensions

Understanding standard cabinet sizes is crucial for efficient kitchen planning. Variations in depth and height exist depending on the cabinet type and manufacturer.

Kitchen cabinet design measurement – Standard cabinet dimensions offer a baseline for planning, but variations exist depending on the manufacturer and style. Custom cabinets allow for precise tailoring to specific needs and space constraints.

- Base Cabinets: Typically 24 inches deep, 34.5 inches high, and available in widths ranging from 12 inches to 48 inches (or even wider in custom designs). Some manufacturers offer shallower base cabinets (18-21 inches deep) for smaller spaces.

- Wall Cabinets: Standard depth is 12 inches, height ranges from 12 inches to 42 inches (or taller), and widths vary similarly to base cabinets (12 inches to 48 inches or more).

- Corner Cabinets: These are designed to maximize corner space. Dimensions vary significantly, depending on the type of corner cabinet (blind corner, lazy susan, etc.). Depth is often similar to base cabinets, but the width is typically determined by the adjacent cabinets.

Appliance Dimensions and Their Impact on Cabinet Design, Kitchen cabinet design measurement

Appliance dimensions directly influence cabinet placement and design. Incorrect planning can lead to insufficient space or awkward layouts.

| Appliance | Typical Dimensions (W x D x H) | Impact on Cabinet Design |

|---|---|---|

| Refrigerator (Standard) | 36″ x 30″ x 68″ | Requires dedicated space, often with adjacent cabinetry for pantry storage. Depth significantly impacts aisle width. |

| Oven (Standard) | 30″ x 24″ x 30″ | Needs space for ventilation and accessibility. Often integrated into a cabinet run. |

| Dishwasher (Standard) | 24″ x 24″ x 34.5″ | Typically integrated under the counter, requiring space for door opening and plumbing access. |

Accurate appliance dimensions should be obtained from the manufacturer’s specifications before finalizing the kitchen design. These dimensions, along with the standard cabinet sizes, inform the overall layout and ensure a functional and aesthetically pleasing kitchen.

Cabinet Styles, Materials, and Design Considerations

The selection of kitchen cabinet styles, materials, and layout significantly impacts both the aesthetic appeal and functionality of a kitchen. Careful consideration of these factors is crucial for creating a space that is both beautiful and efficient. This section will explore various cabinet styles, materials, and design considerations to aid in informed decision-making during the kitchen design process.

Comparison of Popular Kitchen Cabinet Styles

The choice of cabinet style influences the overall look and feel of the kitchen. Three prevalent styles—Shaker, slab, and raised panel—offer distinct aesthetic and functional characteristics. The following comparison considers aesthetics, functionality, and cost implications.

- Shaker: Characterized by a simple, flat center panel recessed within a frame, Shaker cabinets offer a timeless and versatile aesthetic. Their clean lines suit both traditional and contemporary kitchens. Functionally, they are durable and relatively easy to clean. Cost-wise, they fall into the mid-range category.

- Slab: Featuring a smooth, flat door without any visible frame or panel, slab cabinets present a sleek, modern look. Their minimalist design maximizes visual space and creates a contemporary feel. While functional and easy to clean, they can show fingerprints and smudges more readily than other styles. The cost is typically moderate to high, depending on the material.

- Raised Panel: This style features a central panel raised above the frame, creating a classic, traditional look. The raised panel adds visual interest and depth. Functionally, they are durable and relatively easy to maintain. Cost-wise, they generally fall within the mid-range to high category, depending on the intricacy of the design and the material used.

Cabinet Material Properties

The material chosen for kitchen cabinets significantly affects their durability, maintenance requirements, and overall cost. The following table summarizes the pros and cons of common cabinet materials:

| Material | Durability | Maintenance | Cost-Effectiveness |

|---|---|---|---|

| Wood (e.g., solid oak, cherry) | High; strong and long-lasting, but susceptible to warping with moisture | Moderate; requires regular cleaning and occasional refinishing | High; initial cost is substantial, but offers long-term value |

| Laminate | Moderate; resistant to scratches and moisture, but can chip or peel | Low; easy to clean and maintain | Low to moderate; affordable but may not last as long as wood |

| MDF (Medium-Density Fiberboard) | Moderate; strong and stable, but susceptible to moisture damage if not properly sealed | Low; easy to clean, but requires careful handling to avoid damage | Low to moderate; relatively inexpensive, but requires careful selection and finishing |

Small Kitchen Cabinet Layouts (8ft x 10ft)

Efficient space planning is crucial in small kitchens. The following designs illustrate how to maximize storage and workflow efficiency in an 8ft x 10ft space.

Design 1: L-Shaped Layout This design utilizes the corner space effectively. A long L-shaped counter provides ample workspace and storage. The sink is placed near the window for natural light and ventilation. Upper cabinets extend along the entire length of the walls, maximizing vertical storage. A small island or peninsula could be added if space permits, providing additional counter space and storage.

Text-based sketch: Imagine an L shape running along two adjacent walls, with the sink placed near the corner of the L where the window is likely located. Cabinets are along the entire length of both walls of the L.

Design 2: Galley Layout This layout features parallel countertops on opposite walls, maximizing workspace and storage in a narrow space. Appliances are strategically placed to minimize movement between tasks. This design is efficient for small kitchens but might feel slightly cramped if not properly planned.

Text-based sketch: Two parallel counters run along opposite 10ft walls, with appliances (refrigerator, stove, oven) placed along one wall and sink and prep area along the other. Cabinets are placed above and below both counters.

Design 3: U-Shaped Layout A U-shaped layout maximizes storage by incorporating three walls. The U-shape creates a natural work triangle between the sink, stove, and refrigerator, promoting efficient workflow. However, this layout can feel confined in a very small kitchen unless ample aisle space is maintained.

Text-based sketch: A U-shaped counter configuration utilizes three walls, with appliances and sink positioned to create a functional work triangle. Cabinets are placed along all three walls of the U shape.

Measuring for Kitchen Cabinets and Installation Process: Kitchen Cabinet Design Measurement

Accurate measurement and precise installation are crucial for achieving a seamless and functional kitchen design. Inaccurate measurements can lead to significant problems, including gaps, misaligned cabinets, and doors that don’t close properly. This section details the process of measuring your kitchen and installing your custom cabinets.

Kitchen Space Measurement

Precise measurements are paramount for custom cabinetry. Begin by sketching your kitchen’s layout, noting wall dimensions, window and door locations, and appliance placement. Use a measuring tape, preferably a 25-foot tape measure for larger kitchens, and a level. Measurements should be taken at multiple points along each wall to account for irregularities.

Wall Measurement: Measure the length and height of each wall section between obstructions (windows, doors, etc.). Record these measurements clearly on your sketch. Measure from floor to ceiling at several points along each wall to account for unevenness. For instance, if a wall is 10 feet long, take measurements at 0 feet, 3 feet, 6 feet, and 10 feet. Record the highest and lowest measurements to determine any variation.

Corner Measurement: Accurate corner measurements are critical. Measure the distance from the inside corner of one wall to the inside corner of the adjacent wall along the floor and ceiling. Also, measure the distance along the walls to ensure the corner is a true 90-degree angle. If not, note the deviation. For example, a diagonal measurement across the corner might reveal a slightly greater distance than the sum of the two adjacent wall measurements, indicating an obtuse corner.

Opening Measurement: For windows and doors, measure the width and height of the opening at multiple points. Record the smallest measurement for each dimension to ensure sufficient clearance for the cabinet. Note the location of any obstructions within the opening, such as electrical outlets or pipes. For example, measure the window opening at the top, middle, and bottom to account for any irregularities. Record the narrowest width and height.

Tools and Materials for Cabinet Installation

The success of cabinet installation hinges on having the right tools and materials. A comprehensive list ensures efficiency and minimizes potential complications.

- Measuring Tape: A 25-foot tape measure is ideal for accurate measurements.

- Level: A 4-foot level ensures cabinets are installed plumb and level.

- Stud Finder: Locates wall studs for secure cabinet mounting.

- Drill: A cordless drill with various drill bits (wood, metal) is essential for drilling pilot holes and securing cabinets.

- Screwdriver (Phillips and Flathead): For various screws and hardware.

- Safety Glasses: Protect eyes from flying debris.

- Pencil: Mark locations for drilling and mounting.

- Shims: Correct minor wall imperfections.

- Caulk: Seal gaps between cabinets and walls.

- Cabinet Screws: Secure cabinets to the wall.

- Wood Filler: Fill any holes or imperfections in the wood.

- Sandpaper: Smooth surfaces after filling holes.

Cabinet Installation Process

The installation process involves several stages, each requiring precision and attention to detail.

| Stage | Steps | Potential Challenges | Solutions |

|---|---|---|---|

| Preparation | Clear the area, verify measurements, locate wall studs. | Uneven walls, electrical wiring. | Use shims to level cabinets, reroute wiring as needed. Consult an electrician for electrical work. |

| Base Cabinet Installation | Install base cabinets, ensuring levelness and plumbness. Secure to wall studs. | Misaligned cabinets, uneven floor. | Use shims to adjust levelness, use a level frequently. Ensure the floor is level before installing cabinets. |

| Wall Cabinet Installation | Install wall cabinets, ensuring proper alignment and spacing. Secure to wall studs. | Difficult access to studs, high ceilings. | Use cabinet cleats for added support, use a sturdy ladder or scaffolding. |

| Hardware Installation | Install cabinet doors, drawer fronts, and hardware. | Misaligned doors or drawers. | Adjust hinges and drawer slides as needed. Use templates to ensure accurate placement. |